Spark Plugs and Jetting

First of all, the usual way of reading the jetting by the colour of the sparkplug insulator nose is wrong. The colour of the insulator is influenced by the jetting and the heat range of the

sparkplug. So an improper heat range sparkplug with correct jetting or a correct sparkplug with wrong jetting will produce a colour that will mislead you in reading the jetting.

Here’s some examples;

1. Your jetting is OK, and your sparkplug is of a relatively hot heat range. The colour of the insulator nose will be a bright grey-white colour. It will make you think that your jetting is lean and make you enrich the jetting. The result is loss of power or/and fouled sparkplug.

2. Your jetting is lean and your sparkplug heat range is too cold. The colour of the insulator nose will be brown, making you think that everything is ok. But you may end up overheating.

Some facts about the sparkplug:

The sparkplug insulator nose must attain the self-cleaning temperature. This is the temperature at which the carbon deposits that form on the nose, burn away. If the sparkplug doesn’t reach the self cleaning temperature, the constantly forming carbon deposits won’t burn away, and the result will be a fouled sparkplug.

On the other hand, too hot of a heat range may not remove the heat sufficiently and cause electrodes meltdown and other associated overheat problems.

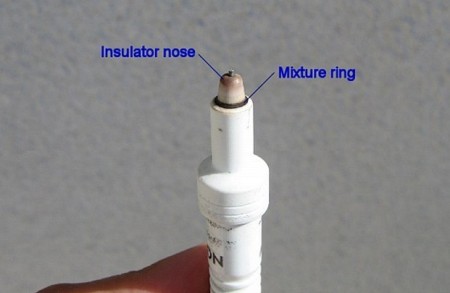

The mixture ring:

This sparkplug is an NGK B9EGV it was used for about 3 races on a racing ZIP SP. The insulator nose is quite clean, that tells you that the heat range was properly selected. The metal part was removed, so you can clearly see what you should look for; the mixture ring. The mixture ring forms on the bottom of the insulator nose. It tells you how the engine is jetted.

From the mixture ring on the picture above, we can say that jetting was close to perfect.

If the jetting was too rich, the mixture ring would thicken, scale up towards the nose tip.

If the jetting was too lean, the mixture ring would become thinner towards the bottom. If the ring became really thin or entirely disappeared, then we could have big overheating problems.

Yes, it’s simple as that. However a much bigger problem is to properly see the mixture ring without destroying the sparkplug each time we check the jetting. A good eye with good sunlight may be enough to see inside, or else a lens with additional light should be used.

Choosing the right sparkplug:

Choosing the right sparkplug is key for good performance. Start by using the sparkplug recommended by the manufacturer of your cylinder. Then after running with your engine in the way it supposed to be used (flat out), you should be able to determine if the sparkplug heat range is correct. As mentioned before, the right heat range will make the insulator nose clean.

If the insulator nose gets carbon deposits on it, the sparkplug is too cold for the use you have.

If the insulator nose gets light gray or white, and/or the electrodes show signs of meltdown, then the heat range is too hot.

The main guideline is, the more time the gas is fully opened, the colder the sparkplug is required.

On a daily used engine there is no need to sharply tune it, so jetting is usually on the rich side to prevent from having overheating problems, but if the engine is used for races, every bit of power should be extracted from it, so jetting should be adapted to weather and track.

These are some guidelines to set the jetting:

Cold, dry (high or no clouds) – air pressure is high; bigger jets.

Rainy, fog (low clouds, fog) – air pressure is low, humidity in air; smaller jets.

Long, straight race track – bigger jets, colder sparkplug heat range.

Short, closed track – smaller jets, hotter sparkplug.